Homologation: FIA 8855-1999

Material: QRT

Non-slip fabric for shoulder and seat restraint

Divisible legrest and seat cushion

Lateral kidney supports

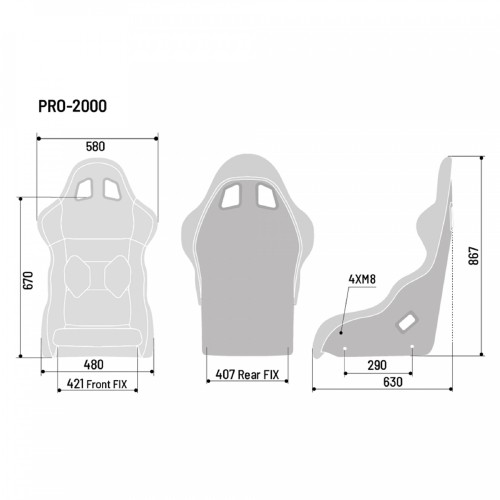

Fixed using M8 lateral fastenings with 290 mm spacing

Fixed using bottom connectors directly on the bases

8kg